Rickenbacker Horseshoe Pickup; Late 1950's Stock. |

ll Page 1 of 1 ll |

THIS PAGE UNDER CONSTRUCTION |

This pickup came out of a 1960 Rickenbacker Steel Guitar which I replaced the pickup in, in an essence of time for the customer, ...knowing I can rebuild the broken bobbin top on this one as casual bench time might allow. It is of the mid-late 1950's stock as evidenced by: (1) The rounded bakelite bobbin extends well beyond the coil. Later post-early 1960's Rickenbacker horseshoe pickups utilized plastic bobbins. (2) The pole pieces are the old style and not the screw-heads of the later plastic bobbins. (3) The coil measures approximately 2.5K ohms; Signifying that it is wound with the thicker (#38?) mid-late 1950's wire rather than the thinner (#42) post-early 1960's wire that measured 6K ohms or more. (4) The magnet is still strong, as opposed to a later 1960's whose magnets were of an alloy meant to take a smaller "charge". NOTE: Rickenbacker apparantly started running out of the bakelite bobbins in the early half of the 1960's. So they reconfigured the horseshoe pickup mainly to use on their bass guitars, and used them on the few Steels they continued making. The bobbin was thereafter made of plastic, the coil was wound with thinner wire, and the horseshoe magnet alloy was made to take a weaker "charge". The last Rickenbacker Steels were made in either 1973 by most sources and another reputable source saying they've seen a very rare 1974 Rickenbacker student model. ------- oOo ------- |

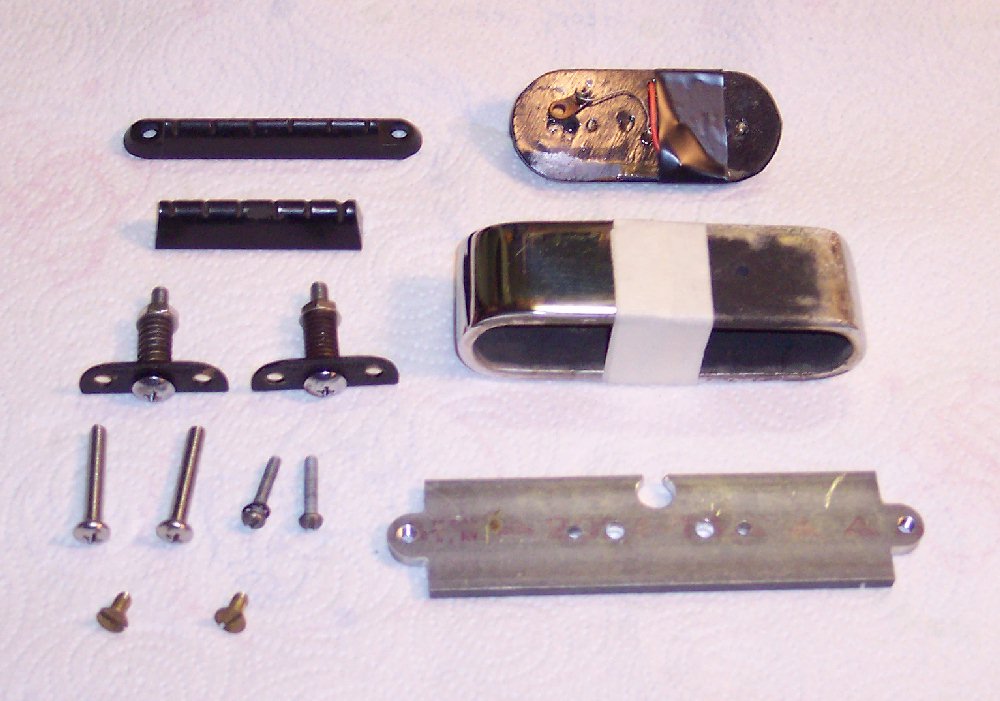

Here the pickup parts are laid out (along with some other unrelated parts that are masked out) with the bottom side of the bobbin and base plate showing. The magnets are stored with their unlike poles joined to maintain their magnet "charge" and keep it even across both pickups. (Always use this holding / storage / shipping configuration when horseshoe magnets are removed from their pickup). |

Here the tops of the bobbin and backing plate are shown. A more detailed image of the bobbin are provided below this image. |

Here's what happens when a person isn't paying close attention and hangs-up the first or last string on a horseshoe bobbin while restringing; I've seen this several times. The bakelite is rather brittle and hanging-up a string on the outer lip of the bobbin top will snap the top, with the shock and break running along the pole pieces as well. Not a difficult repair because the coil was not damaged. The repair will entail building a mold upon a thin sheet of waxed manila folder paper that is cut to tuck in between the coil and bobbin top. Black epoxy is then carefully poured into the mold level with the top surface of the bobbin. A tooth texture is engraved along the broken bobbin edge to make sure the epoxy has something substantial to mechanically grip. The pickup is then re-potted to close the tiny gap the manila mold will leave between the coil and repaired bobbin top. ~~~~~~~ Loose horizontal black tape here is securing the coil for storage. The vertical black tape at the arrow is securing the intact lead wires which are extremely delicate where they meet the coil wires on these pickups. |

^ |

V |

v |